| Machine Name |

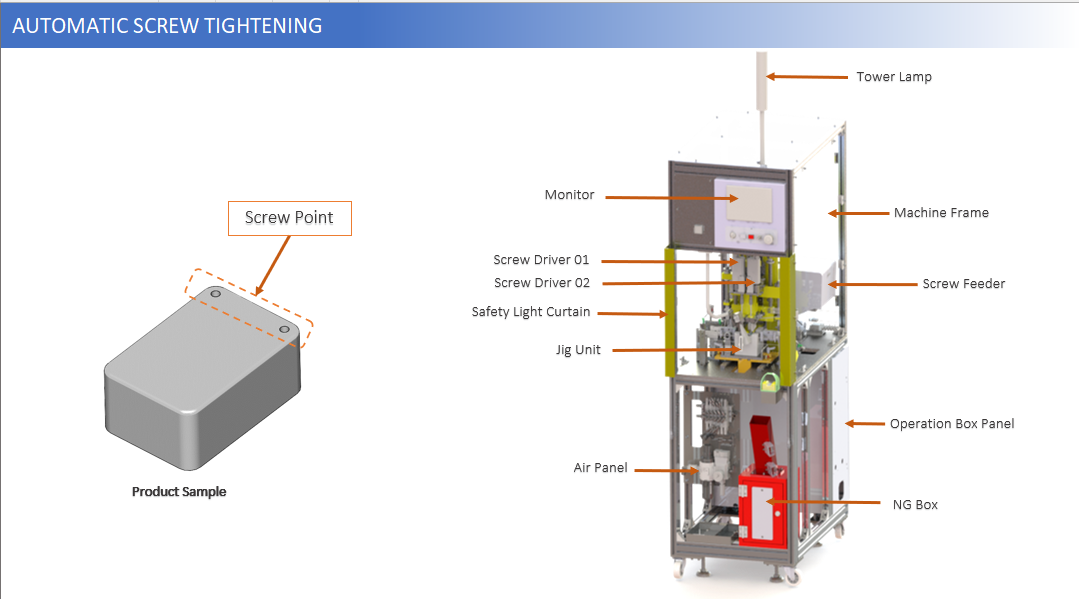

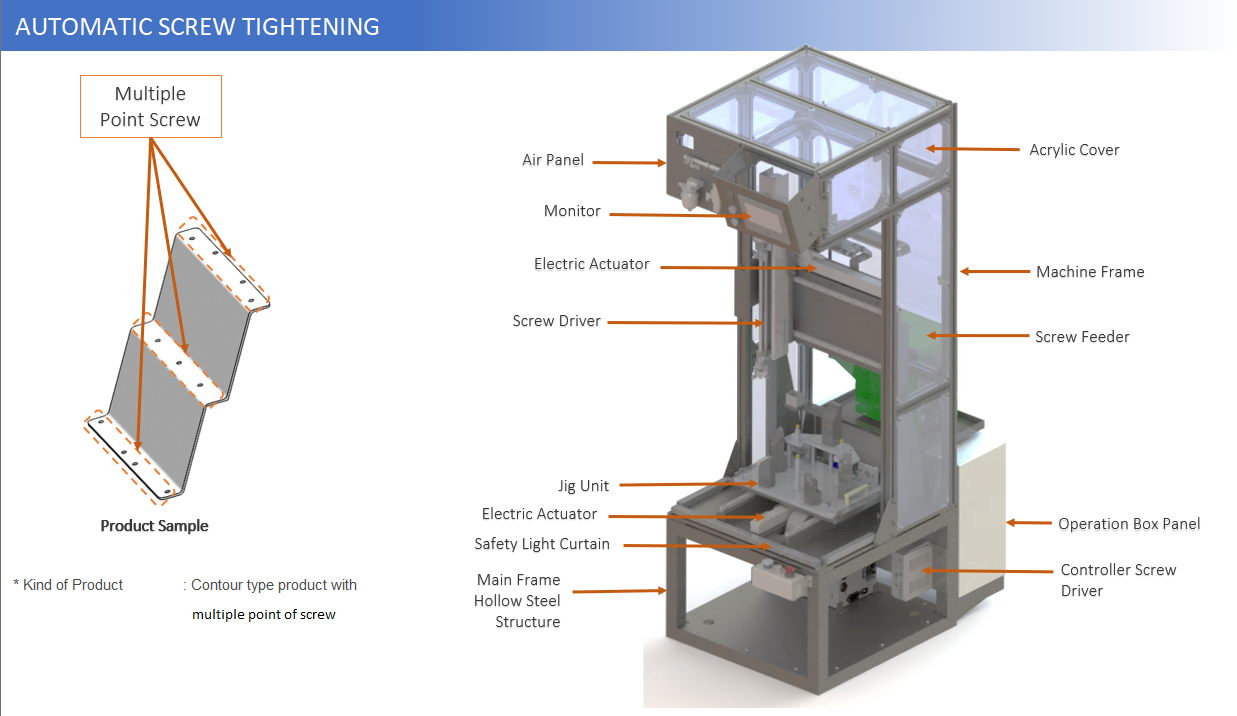

Automatic Screw Tightening |

| Machine Type |

Screw Tightening – Single Screw Driver |

| Function |

Screw Tightening |

This machine used to screwing process. By using an electric actuator on X,Y and Z axis movement allows this machine to do the screwing process at many points precisely and automatically. |

| Tightening Device |

Screw Driver |

| Machine Dimention |

1000x700x2000 |

| Machine Color |

Powder Coating Evory / Conditional Based on Request |

| Machine Weight |

400 Kg |

| Accessories |

PC, Towel Lamp Indicator (Conditional) |

| Machine Time (Screw Tigtening Process) |

3,5 Sec |

|

| Air Supply |

0,4 Mpa |

| Input Power |

220 VAC, 1 Phase, 50Hz |

| Current Max |

10 Ampere |

| Specifications |

Control |

PLC |

| Operation Panel |

Touch Panel / Conditional Based on Request |

| Output Operation |

|

| External Input |

|

| Note |

This machine works automatically.Operator set up the product into jig manually, press start button, then the screw tightening process run automatically. |

<

<